Industrien

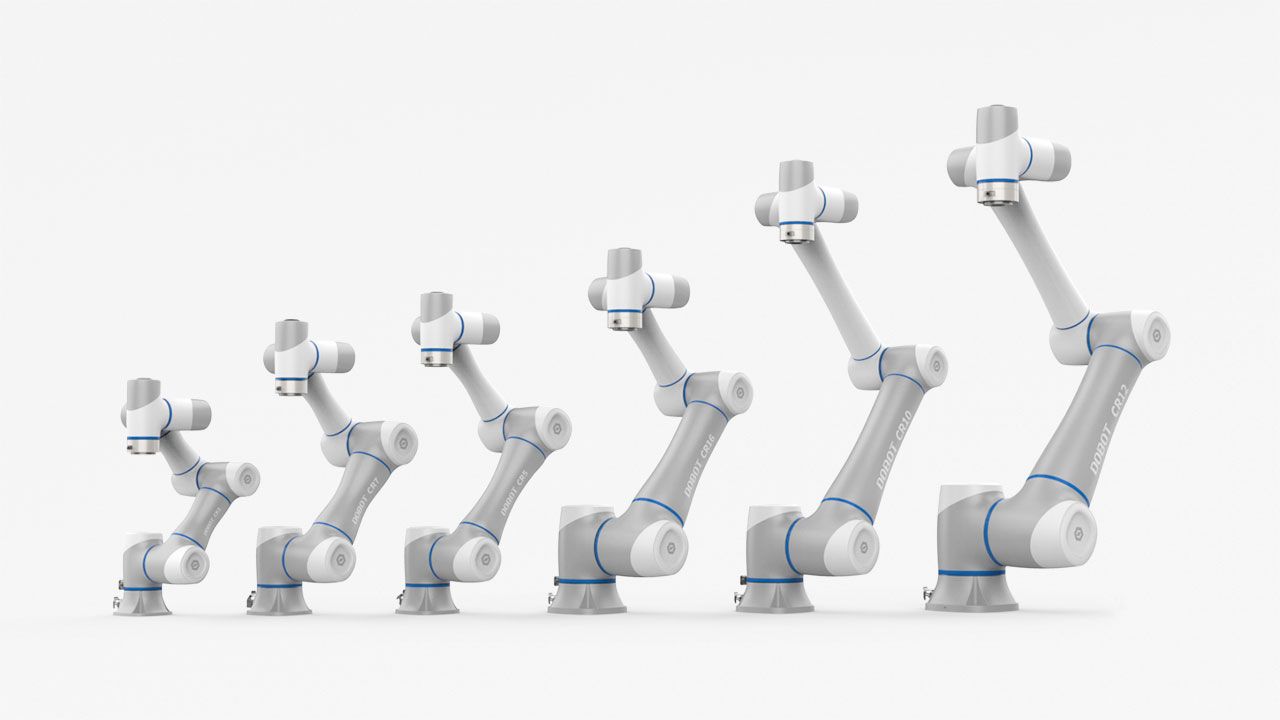

Kollaborative Roboter bieten Unternehmen in verschiedenen Branchen wettbewerbsfähige Vorteile. Mehr erfahren

Mehr erfahren

Anwendungen

Die Roboter von Dobot können eine Vielzahl von Aufgaben noch effizienter ausführen. Mehr erfahren

Mehr erfahren

-

Über Dobot

Erfahren Sie mehr über den führenden Anbieter von Robotiklösungen. -

Werden Sie Vertriebspartner

Schließen Sie sich dem Dobot-Vertriebsnetz an, um die Automatisierung zu beschleunigen. -

Wenden Sie sich an uns

Die Transformation der Automatisierung ist eine gemeinsame Anstrengung. Machen wir es gemeinsam.